| Sign In | Join Free | My qualitytoyschina.com |

|

| Sign In | Join Free | My qualitytoyschina.com |

|

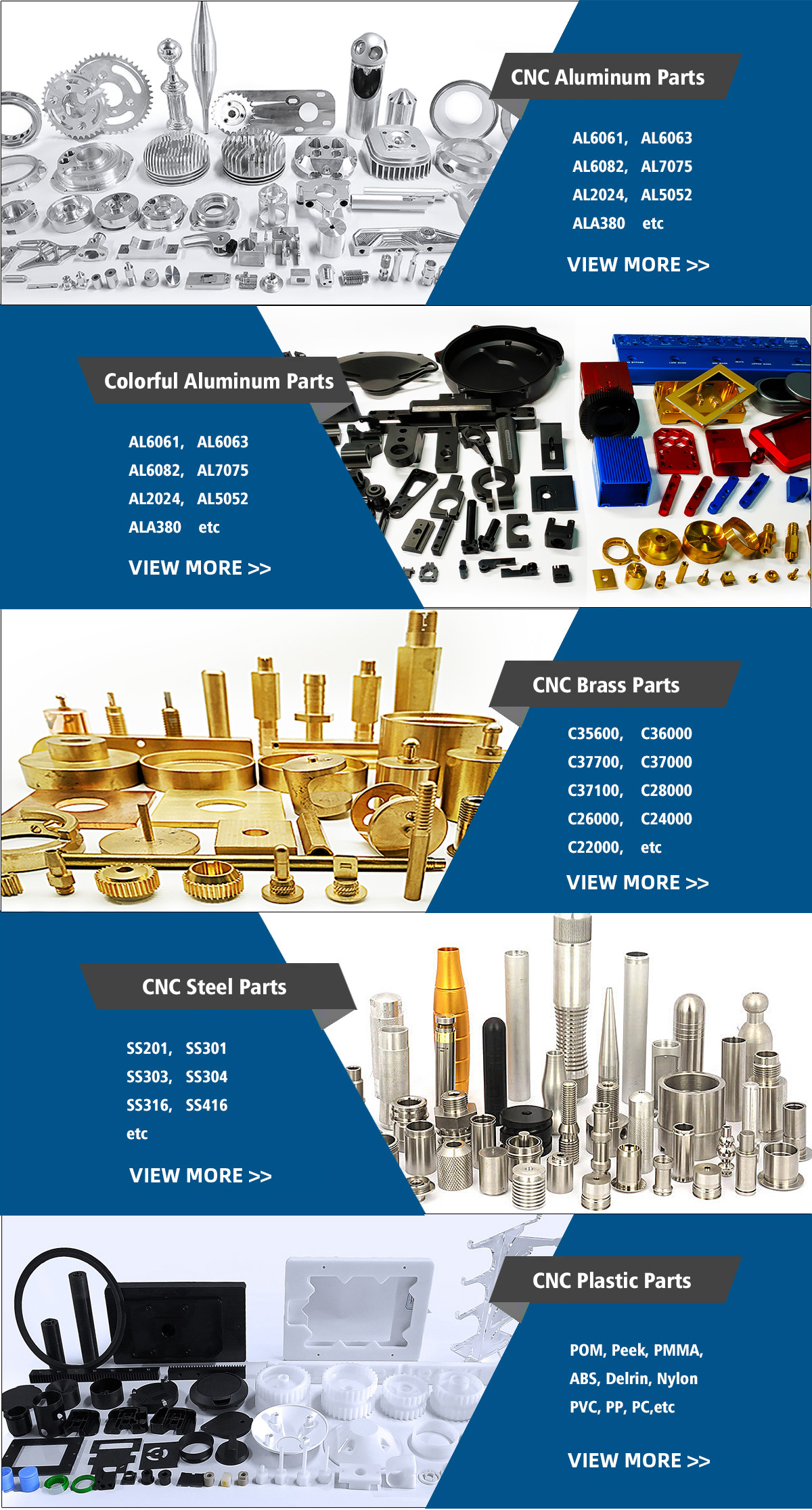

| Categories | CNC Milling Machining Parts |

|---|---|

| Brand Name: | OEM/YMP |

| Model Number: | custom made precision metal parts |

| Place of Origin: | Guangdong, China |

| MOQ: | 100 |

| Price: | $0.73-1.145 piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 pieces per day |

| Delivery Time: | 7 days |

| Packaging Details: | Inner pearl button, outside carton box, or customized |

| CNC Machining or Not: | CNC Machining |

| Type: | Broaching, DRILLING, Etching/Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Micro Machining or Not: | Micro Machining |

| Material: | Aluminum Alloy,Brass Alloy,Stainless Steel,etc. |

| Tolerance: | 0.01- +/-0.005mm |

| Drawing Format: | 3D/CAD/DWG//STEP/PDF |

| Surface treatment: | Sandblasting,Anodizing,Plating,Polishing Etc |

| QC control: | 100% Inspection Before Shipment |

| Certification: | ISO9001:2008 |

| Application: | Machine spare parts,Tools,office equipment,etc. |

| Our advantage: | Superior in quality,reasonable in price and deliver on time |

| Process: | CNC machining(turning, milling, drilling) |

| Term of Payment: | T/T,paypal,Escrow,Trade Assurance |

| Product Name | Customized Sheet Metal stamping part |

| Material | SPCC,mild steel, stainless steel, aluminum |

| Machining Equipment | laser cutting machine, bending machine, welding machine, 3-5 axis cnc milling machines, CNC lathes, EDM machines, Grinding machines. |

| Finish | painting, powder coating, plating, plising, anodize |

| Inspection equipment | CMM, Tool microscope, multi-joint arm, Dial gauge, Marble platform, Roughness measurement, Digital height gauge, caliper, Projection machine, Hardness tester and so on. |

| Drawing Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Packaging | 1.Standard strong carton package + Pallet/ Wooden case |

| 2. Per customer's requirements | |

| Delivery | Sample: 5-10 days |

| Mass Production: 15-30 days depends on quantities | |

| Application | Aerospace, Aviation, Agriculture, Marine, Electronic, Automobile, Communication, Drone, Medical, Solar energy, Home Appliance, etc |

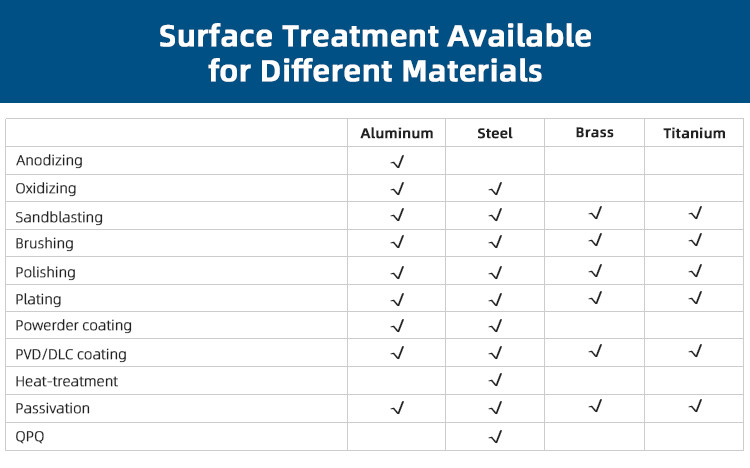

Sandblasting is one of the commonly used surface treatments of hardware products, which can improve the cleanliness and roughness, and increase the adhesion and durability between products and coatings. Therefore, many surface treatments choose sandblasting as their pretreatment, such as sandblasting+oxidation, sandblasting+electroplating, sandblasting+electrophoresis, sandblasting+powder spraying, sandblasting+baking, sandblasting+passivation, etc.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

|